DIMAC Products

Products Guide

DIMAC provides 19 feeders in 6 categories. This page introduces them by functions. We hope you can take best product for your use.

We have options available as needed, so please check. Please see the price list for the price of each product.

Information on products sold in the past is posted on production discontinued models.

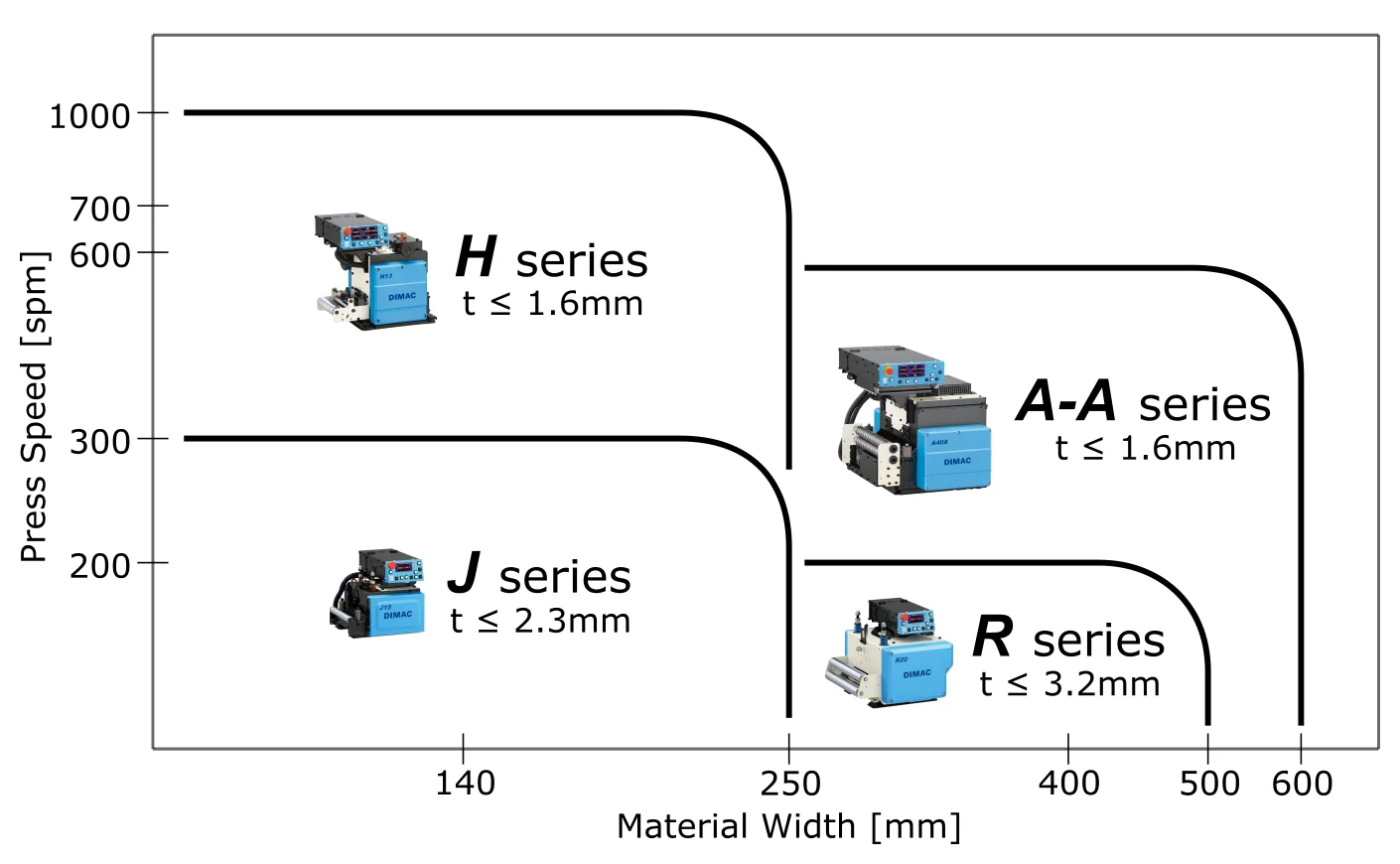

The Key to Select Series

- When sending sheet material, please select T series

- Recommend that you use the G series (grip feeder) when rolling or scratching of material due to roll feed is a problem.

- Please select the roll feeding machine from the graph below according to the rotational speed of the press, material width and thickness.

※ The graph shows the selection range for each series based on Press Speed [spm] and Material Width [mm]

R Series

Standard model with air cylinder release mechanism. Maximum follow speed 200spm, material thickness up to 3.2mm.

| Model | Material Limits | Max Speed[spm] | |

|---|---|---|---|

| Max Width[mm] | Max Thickness[mm] | ||

| R20 | 200 | 3.2 | 200 |

| R30 | 200 | 3.2 | 300 |

| R40 | 200 | 3.2 | 400 |

| R50 | 200 | 3.2 | 500 |

J Series

Compact roll feeder with air release mechanism for high-speed response. Suitable for non-metallic materials and thin metal sheets. Material width up to 250mm, maximum follow speed 300spm.

| Model | Material Limits | Max Speed[spm] | |

|---|---|---|---|

| Max Width[mm] | Max Thickness[mm] | ||

| J06 | 250 | 1.2 | 70 |

| J15 | 250 | 2.3 | 150 |

| J25 | 250 | 2.3 | 250 |

H Series

High-end model with electromagnetic release mechanism. Uses dedicated encoder, supports up to 1000spm. Electromagnetic release mechanism eliminates need for air piping and enables numerical control of material pressure.

| Model | Material Limits | Max Speed[spm] | |

|---|---|---|---|

| Max Width[mm] | Max Thickness[mm] | ||

| H07 | 200 | 1.2 | 75 |

| H13 | 200 | 1.6 | 130 |

| H25 | 200 | 1.6 | 250 |

A-A Series

Supports up to 600spm. Enables longer feed than conventional high-speed NC roll feeders, material width up to 600mm. Electromagnetic release mechanism eliminates need for air piping. Features automatic thickness adjustment.

| Model | Material Limits | Max Speed[spm] | |

|---|---|---|---|

| Max Width[mm] | Max Thickness[mm] | ||

| A40A | 400 | 1.6 | 120-400 |

| A60A | 600 | 1.6 | 150-600 |

G Series

Grips and transports materials with grip surface. Less prone to pressure marks compared to roll transport. Uses electromagnetic release mechanism, no air piping required, material pressure can be numerically controlled.

| Model | Max Speed[spm] | Max Feed Length[mm] | Material Limits | |

|---|---|---|---|---|

| Max Width[mm] | Max Thickness[mm] | |||

| TG4 | 1000 | 40 | 200 | 0.8 |

| G11 | 600 | 110 | 200 | 0.8 |

T Series

Two feeders positioned on left and right of die perform material feeding and withdrawal. Suitable for main use with sheet materials.

| Model | Material Limits | Max Speed[spm] | |

|---|---|---|---|

| Max Width[mm] | Max Thickness[mm] | ||

| T20 | 200 | 3.2 | 200 |

| T30 | 200 | 3.2 | 300 |

| TR50 | 200 | 3.2 | 500 |

| TJ06 | 200 | 1.2 | 70 |

| TJ15 | 200 | 2.3 | 150 |

Features of product series

Dimac feeding devices adopt different mechanisms for each series as shown in the table below.

| Series Name | Material Conveying | Holding Method | Feeding Method | Pressurization Method | Material Release<br />(Normal Operation) |

|---|---|---|---|---|---|

| R Series | Coiled material | Roller | Motor | Spring | Air Cylinder |

| J Series | Coiled material | Roller | Motor | Spring | Air diaphragm cylinder |

| H Series | Coiled material | Roller | Motor | Electromagnet | Electromagnet |

| A-A Series | Coiled material | Roller | Motor | Electromagnet | Electromagnet |

| G Series | Coiled material | Grip | Motor | Spring | Spring |

| T Series | Sheet / Coiled material | Roller | Motor | Spring | T / TR : Air Cylinder TJ : Air diaphragm cylinder |

| Series Name | Max. Stamp Speed<br />[spm] | Compressed Air | Adjusting to Pressing Force for Material | Unclamping Material<br />(A Case to Insert Material) |

|---|---|---|---|---|

| R Series | 200 | Required | Adjusting Screws (Manually Operated) | - |

| J Series | 300 | Required | Adjusting Screws (Manually Operated) | - |

| H Series | 1000 | Not Required | Numerical Control | Switch |

| A-A Series | 600 | Not Required | Numerical Control | Switch |

| G Series | 1000 | Not Required | Numerical Control | Switch |

| T Series | 200 | Required | Adjusting Screws (Manually Operated) | Switch |

The models of H series and G series synchronize operation with press machine by a private rotary encoder (rotation sensor). Other models do so by two synchronizing signal. The products which are syncronized by a rotary encoder cannot cope with servo press machine.

Options

We offer many options. They can be used in combination according to the situation. Please refer to the price list page for the compatibility between each product and options.

- Remote Box: RC6A

- Feed Direction Switch : DS6

- Data Bank : MP6

- Feed Complete Output : FF6

- Feed-in-Progress Output : BS6

- Feed Condition Measurement : TC6

- Optical Material Break Sensor

- Pull Specification

- Controller Offset

- Swing Cover

- Urethane Roll

- Silicon Roll

- BBC Roll

- Central Clamp Roll

- Separate Roll

- Apron Roll

- Slide Plate

Remote Box: RC6A

It enables operation of one cycle, jog, roll open/close, and Sync Release from a location away from the main controller. Cable length can be selected from 3m or 5m. The speed of one cycle by this unit is only the speed during jog. For safety, operation from the main controller is prohibited when operating with RC6A. Also, operation with RC6A is not possible during setting for synchronized operation with the press machine.

Feed Direction Switch : DS6

It enables switching of the roll rotation direction. Both feeding and pulling of materials are possible. An additional material break sensor can be connected, and it is possible to switch which sensor is enabled according to settings. This unit is installed by stacking on top of the main controller.

Data Bank : MP6

It can store up to 99 sets of settings such as feed length, feed angle, and release conditions. This eliminates the need to re-enter feed conditions every time the die is changed, and they can be recalled. Also, by linking some of the 99 sets, program operation similar to conventional multi-stage feed units is possible. The maximum number of feeds per stage is 99. When combined with feed direction switch DS6, feed direction reversal is also possible. This unit is installed by stacking on top of the main controller.

Feed Complete Output : FF6

It outputs a signal when material feeding is completed. It can also be used when interlocking with other peripheral equipment is required. Output enable/disable can be selected by operation switch and external input. When combined with feed-in-progress output BS6, operation equivalent to the conventional Feed Master option (alternating operation with press) is possible. This unit is installed by stacking on top of the main controller.

Feed-in-Progress Output : BS6

It outputs a signal when feeding material. It can also be used when interlocking with other peripheral equipment is required. When combined with feed complete output FF6, alternating operation with press equivalent to the conventional Feed Master option is possible. This unit is installed by stacking on top of the main controller.

Feed Condition Measurement : TC6

This is an option that automatically inputs the feed angle of our feeder and the press operating speed setting value. Please set the feed signal on the press side in advance. Then, by operating the press in trial mode, the feed signal is measured and the feed angle "Feed Angle" and press operating speed "spm" of our controller are automatically calculated (patent pending). Recommended when operating the press in pendulum or irregular motion, where it is difficult to set by numerical conversion. This unit is installed by stacking on top of the main controller.

Optical Material Break Sensor

An optical sensor that detects material breakage. The sensor sensitivity can be adjusted according to the environment. It can be installed on all models, but for T series, it can only be used in coil mode and single mode. Installation method and position differ by model. There is no compatibility between products.

Pull Specification

Image coming soon

The feeder is installed on the downstream side of press processing and pulls the material. Please select this when you do not want to leave marks such as roll marks on the product, or when the material is thin and easily warped.

Controller Offset

The controller of models with the controller mounted on the top center of the feeder (J and R series except J06) is shifted and installed to the side away from the press machine. Effective when the feeder interferes with the press, etc. when installing.

Swing Cover

A cover that covers the roll section of the feeder. Helps improve safety and protect materials.

Urethane Roll

A roll with urethane resin wrapped around an iron core. Effective for preventing pressure marks on materials that might be flattened by metal rolls and improving feed accuracy for slippery materials. However, chemical resistance and durability are inferior to standard rolls. Cannot be used with H series and A-A series due to their small roll release stroke.

Silicon Roll

A roll with silicon resin wrapped around an iron core. Compared to urethane rolls, it has superior non-adhesiveness, heat resistance, and chemical resistance, making it suitable for transporting film materials, adhesive tapes, and printed materials. However, its abrasion resistance is inferior to urethane rolls, and it is more prone to slipping. Similar to urethane rolls, cannot be used with H series and A-A series due to their small roll release stroke.

BBC Roll

A roll that has undergone blast and bluing treatments. Features a high friction coefficient on its contact surface with materials, enabling the transport of materials with minimal slippage. A drawback is that materials are prone to getting scratched. For delicate materials, an option for a separate roll that allows the central part of the material to be avoided is recommended.

Central Clamp Roll

An option specifically for the A-A series. By using a central clamp roll, the minimum material width that can be handled is reduced by up to 50mm compared to standard rolls. A caution is given that the transport capacity will change, and further details are referred to "this document".

Separate Roll

Rolls can be installed separately. Can be adjusted according to material width.

Apron Roll

An apron-shaped roll. Used to stabilize material feeding.

Slide Plate

A slide plate that assists in material feeding. Can be selected according to material type and thickness.

DIMAC Products Consultation

Considering introducing DIMAC products? We propose the optimal feeder for your production line.

Contact Us